Well, you guys have sucked me in.

I wrote a couple weeks ago about my failed OBC (in this thread:

https://myimiev.com/forum/viewtopic.php?t=5218), basically asking if there was a simple fix or if I needed to scrap the car. Learned of this thread, bit the bullet and read the whole thing. Which was hard, because I know just enough about electronics to be dangerous. My problem is on the AC input side. The car still drives and charges the 12V battery, so the DC/DC is fine and the 20 amp fuse in the MCU is good.

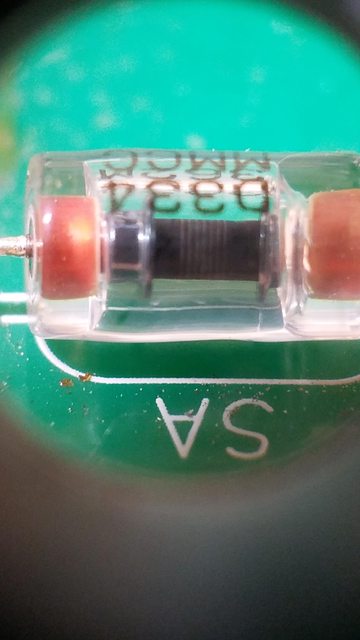

I have my OBC boards out of the car. C106 (2.2 µF) has oozed gray goo all over R106, the non-fused 4.7 Ω ceramic resistor. As near as I can tell, R106 is still good. It measures 5.1 Ω. But R105, the other ceramic resistor with an internal fuse is open circuit. (At least I think so, because sticking wires deep under the waffle plate to get at those leads is tricky.) N on the waffle plate to the neutral Faston is open circuit. Snubber caps are intact, but have a slight brownish hue. The glass-tube component marked "SA" (spark arrestor?) is open circuit both directions, but I don't know what it is, let alone how to test it. Any suggestions? I also found some contacts on the flex circuit to be bent. (Which I might have done inadvertently, or is inconsequential since I understand some of those lines are redundant.)

My approach to this is to look at the potential show-stoppers first.

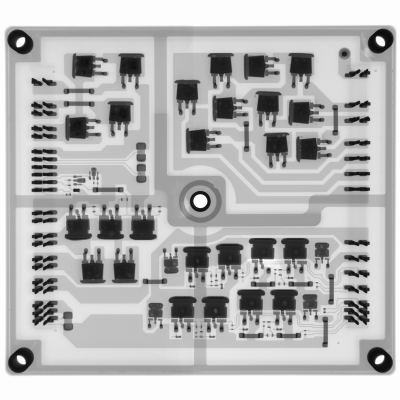

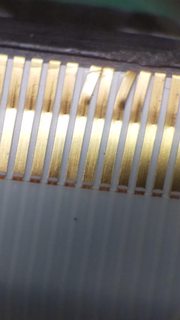

1) I've checked the diode drops in the waffle plate. They look good, except for the same issue as @adam on page 101. Between points 12 and 13 I got the expected .6 V in one direction, but 1.6 V in the other, and significantly lower resistance values in the lower right quadrant. (16k vs. 90k and 200 vs.1k.) Never saw an explanation for that. Is it OK?

2) I'd prefer to do this once. Since if successful this repair will save me 1000s of dollars, it makes sense to me to just buy a desoldering station to remove the waffle plate to make the rework easier and more reliable. I've never used one, but I have used a hand-held spring plunger type. Is this something a noob can master quickly? It will likely be used only for this repair and then sold (perhaps to the next person with a dead i-MiEV OBC?). Any recommendations? Just go by the reviews at online retailers?

3) If in fact my fused 4.7 Ω resistor is toast, what then? None of the rectangular resistors I've found will fit between the boards, and I'm not a fan of some of the apparently effective but hillbilly-looking hacks some have been forced into. I did find this at digikey:

https://www.digikey.com/en/products...loric-bc-components/AC07000004708JAC00/595613 . Is it a good replacement for the non-fused R106? What about the fused one, R105? Is there an inline thermal fuse I could put in series with an axial resistor? If there is such a thing I can't make enough sense out of the P10K data sheet to know how to spec one. How necessary is that fuse, seeing as how the resistors themselves seem to fill that role pretty well?

4) Even if all goes well it gives me pause that several people have replaced the ceramic resistors and tested the relay, but still keep blowing resistors after a repair. Sure seems to me that something is happening upstream of the relay and resistors. I hadn't seen anything discussed about that (other than checking continuity across the flex and its connectors), except that @siggs found a faulty connection to the relay:

https://myimiev.com/forum/viewtopic.php?p=45806#p45806 . He also referenced another person doing i-MiEV charger repairs who had found the same problem repeatedly. A bad solder joint doesn't seem like a repeatable problem. Maybe a bad run of relays and the problem is internal? I found this with a 105 °C limit. Is that really high enough, as stinkin' hot as this charger gets?

https://www.digikey.com/en/products/detail/cit-relay-and-switch/J114FL1CS165VDC-41/14002174

5) One last thing (for now). I think I remember seeing a photo of an oozed capacitor in the doghouse on top of the OBC lid. I took the metal cover off mine and found a plastic cover underneath. The plastic cover is on there pretty solid, enough that getting it off will likely result in broken plastic. Is there a trick I'm not seeing?